Here at Metalworking Solutions we build OEM manufacturing components for the following industry segments every day.

- Engineering machinery

- Mining equipment

- Forestry machinery

- Road equipment

- Machine tool equipment

- Marine equipment

ISO 9001 & ISO 3834

Simple 3-step process to quickly obtain a quotation

Step 1: Leave your information, and within 24 hours, our engineering experts will contact you.

Step 2: Confirm your drawings and choose your production process and materials.

Step 3: Receive a quotation and production lead time.

Understand our process technology

MKV40 - 600 Laser cutting machine

Komatsu &HUAHEN plasma cutting machine

CNC flame cutting machine

Nine roll sheet flattening machine

Komatsu 8 axle pivot welding robot

HUAHENG welding robot

Customization based on your design, we can do much more than just this.

frame

H-beam

side beam

fore

miniature mast

asphalt hopper

Customization based on your design, we can do much more than just this.

frame

H-beam

side beam

fore

miniature mast

asphalt hopper

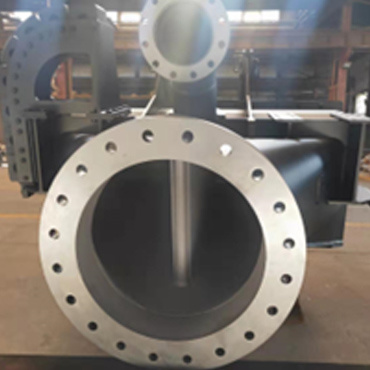

IHC curved sludge tube

IHC cover

Tray , Cable

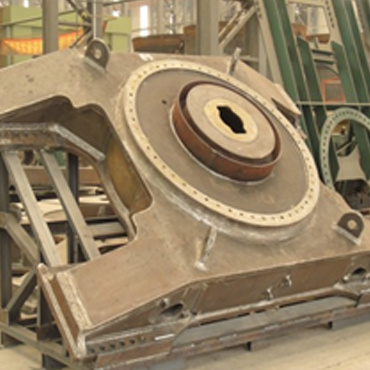

Rotary Ditcher

Bucket

Side frame

Bucket

Rear frame

Rockerarm

By choosing our customization service, we can offer you the following conveniences.

·Flexibility: Custom welding structural components are designed and made to meet exact project or product needs.

·Optimized Design: Custom manufacturing tailors designs for improved performance and efficiency in specific applications.

·Improved Quality: Rigorous quality control ensures reliability in custom production.

·Cost Reduction: Custom design minimizes waste and enhances production efficiency, leading to lower costs over time.

They all chose Dongxing

Our company's products primarily cater to market such as China, Japan, Germany, Canada, the United States, Italy, France, Belgium, the Netherlands, and Norway, as well as Austria

Global Customers

Exporting Country